George Wilkinson

Wood and Heat Pumps: Components for Sustainable Building

100 years ago, old-growth trees were used to make columns, girders, and planks for commercial buildings. Butler Square in Minneapolis is a good example of this applied construction technology. It was a sound construction strategy; 100 years of service is impressive. However, limitations arose from the availability of old-growth trees to be used for this purpose.

Design Problem Solving: Details Count

Gunter Dittmar was my icon in graduate school. He was a despondent German expatriate bombed into depression while growing up in Berlin during the Allied blitz. Amid his slow and thoughtful speech was a bit of genius. He understood that the "problem solving process" and the “problem seeking process” involved keeping the "levels of abstraction" aligned and not mixed up.

For example, you can't solve the big picture if you're focused too early on how many doorknobs and how much they cost each. Ultimately you care about the doorknobs, but only in the right sequence and at the right time.

“The is nothing more worrisome that the wrong question answered well” (quote from South American Architect on TED talks)

The reasons for the mix-ups are many are 1) participants competing for influence in the process and sowing mixed levels just to be in the conversation, 2) sometimes the logical structure of the issue is simply misunderstood and the conversationalists get down the rabbit hole, 3) the participating silos have standards of practice that run in opposition to one another, 4) the participants don't like one another, and 5) disorderly allocation of risk (hours of effort in dollars) etc .

In any event put first things first as you move from concepts to details.

Wood and heat pumps; old made new again

100 years ago, old-growth trees were used to make columns, girders, and planks for commercial buildings. Butler Square in Minneapolis is a good example of this applied construction technology. It was a sound construction strategy; 100 years of service is impressive. However, limitations arose from the availability of old-growth trees to be used for this purpose.

50 years ago mechanical designers in the Minneapolis area took the innovative step of applying emerging heat pump technology to indoor climate applications. It was revolutionary. Systems were simplified and installed costs plummeted. It was a serviceable technology for many commercial applications.

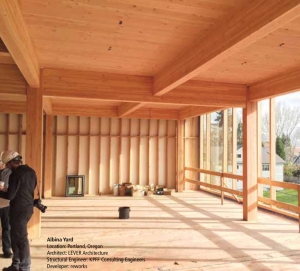

Fast forward to today, and the old is being made new again. The fabricated, structural timber industry now makes components to build frames and floors without relying on old-growth trees. To the contrary, 12 to 14-year-old trees are farmed and harvested to make glue-laminated products for the construction of timber frames and CLT floor systems (cross laminated timber).

Application of heat pumps is being used for high-efficiency indoor climate systems. The hydronic water piping systems move the energy around the building to where it's needed. The side of the building in sunlight sheds its excess heat (aka cooling) to the shaded side of the building requiring heating. This distribution by way of the heat pumps leads to reduced energy consumption for indoor climate and comfort.

It turns out that the many energy-saving advantages of wood when combined with high-efficiency indoor climate squarely addresses the issues of energy conservation needed in this era of global warming brought by man's activity.

Care taken in the building industry can make a big difference; join the movement!

(see the blog post at this site: “Timber and Advanced Energy Project Planned in the Upper-Midwest.”)

Innovative site selection and program development

Visible City (Jon Commers and his group) are on the midwest planning scene. They are analysts and planners using high end business intelligence tools including applied GIS (Geographic Information Systems). These tools crunch data in many ways including producing "smart maps": visualizations that reveal hidden development opportunities. Users of the visuals are often heard saying: "I haven't seen that before (despite all my driving around)."

SIPS are changing how we build

Extreme Panels Technology in Cottonwood MN is changing how we build. Structural Integrated panels ("SIPs") combine structure with high-efficiency enclosures and rapid on site assembly. Radically reduced construction periods combined with very low operating expenses make SIPs a BIG player in the design and construction of sustainable architecture.

Contact Terry Dieken or Don Jahnke at 800 977-2635 for more information.

Sound and Ethical Business Practices for Integrated Services

(disclaimer: this document is solely the opinion of George Wilkinson and Wilkinson Building Advisors and does not represent that of any of its clients or employees)

Introduction

This is the first in a three part series addressing best practices and ethics in the AEC business community (“Architecture/Engineering/Construction”)

In the middle of the last century, various practitioners began to assemble teams of designers and builders under single contracts and the label “design-builders” was coined and applied to these business arrangements. This was a watershed idea provoked substantial protest in special organizations such as the AIA. It was not until the last decade or so of the last century that the AIA recognized the role of design-builders. Since then what started as a revolution has become ordinary. In fact, the language is even changing still, for example "integrated project delivery."

Amid all of these changes and in this writer's opinion, there are several themes: i) value arises when design and construction are closely intertwined in the earliest planning stages of a project, and ii) integrated delivery requires effective interaction between a wide variety of professional disciplines.

Ethics and the "Shop Drawing" anecdote

Ethics and the “Shop Drawing” anecdote (an editorial, 041421)

(disclaimer: this document is solely the opinion of George Wilkinson and Wilkinson Building Adviors, and does not represent that of any of its clients or employees)

Ethics: “Moral principles that govern a person’s behavior or the conducting of an activity”

Morals: “Standards of behavior or beliefs concerning what is acceptable”

Professional: “A person competent in a particular activity”

Good Design-Build Leads to Innovation

The cultural headwinds have long been on the bow of the so-called design-build movement. It took nearly 50 years of cultural warfare for the various participants to see their integrative potential.

It is easy to see how the cultural divide is built into the DNA of the various designers, engineers, builders, salespeople, financial engineers, and business managers; they are all different people with different worldviews and ways of behaving. The marketplace finally demanded cooperation and collaboration. By the 1990’s, the acceptance of the design-build approach was no longer in dispute.

Note to Investors: the Business Case for Engineered Timber

Applied technology in the building industry is now at a tipping point. The intersection of timber construction technologies with indoor climate energy exchange and management is creating powerful new market opportunities.

FFE: Furniture, Fixtures, and Equipment

FFE - Furniture, Fixtures, and Equipment - (fixed or otherwise) are needed to complete your project and are not always expressly included in traditional design and construction services.

Examples are:

- Security systems (designers and builders don’t want the liability)

- Data and communication systems (often part of the business work flow)

- Furniture and accessories (includes plants and specialties)

- Modular furniture and work stations (often called “cubicles”)

- Decorations (includes wall art)

- Special equipment (cooling systems for computer equipment etc)