George Wilkinson

Free Whitepaper: Project Fitness Guidelines

Free Whitepaper: Project Fitness Guidelines

We've made a set of checklists about how to execute successful projects, called the Project Lab Series. They are designed to inform investors, owners and designers alike.

Download the Project Fitness Guidelines now.

Wellness mission at Wilkinson Building Advisors

(Atlanta Botanical Gardens and Anderson Japanese Gardens Visitor Center)

A core mission at Wilkinson Building Advisors (formerly The Wilkinson Project Group) is to promote Wellness through the application advanced Mass Timber and Indoor Climate design and construction technologies. Though broadly applicable to wellness of persons and the planet, WBA focuses on education, health care, and housing. WBA works at the intersection of news, knowledge, collaboration, and best design and construction practices.

MicroSoft PowerBI and SharePoint

Update

For Constrution companies that are "spreadsheet centric" (xls), Microsoft has devised a powerful and economical set of tools and workflow. Simply put, content from xls worksheets are pulled into SharePoint and manipulated in PowerBI. PowerBI provides data views limited only by the Users imagination. Because SharePoint rides the web, this container of data is available to a team whether down the hall or across the planet. More to follow later..., this is just my share on a Friday afternoon in the Covid-19 pandemic.

The original post follows

(My recusal; I have never been a MicoSoft evangelist, only a critical user.)

Many persons rely heavily on spreadsheets and they have been around for nearly 40 years.

In my opinion, the breadth of their use sometimes resulted in a kind co-dependency. By the turn of the century, in the opinion of this writer, MicroSoft Excel began to stall out. It was becoming complicated for the average user and there were big gaps in areas of application. In particular, database-like operations were awkward and often required a specialist for set-up.

Happily as MicroSoft began to catch up in the area of “knowledge worker”, web-based operations, useful tools began to emerge. In particular PowerBI as an “app” in Office 365 suite came on the scene. Both Gartner and Forrester reviews favorably recognize MicroSoft’s achievements.

PowerBI cleverly supports organizations dependent on spreadsheets. It provides a way to “source” multiple spreadsheets, to combine and manipulate them, and to graphically visualize the results. This process is sometimes call “Applied Analytics” and “Business Analytics.”(all the buzz right now)

To be fair, even though MicroSoft would like to hype revenue and sell this as a consumer product, there is a learning curve for Office 365 and the PowerBI app. For the average small and mid-sized company, hiring some start-up help may be wise.

Wilkinson Building Advisors and its partners can help you quickly to take off the training wheels and wring competitive advantage out of this suite of tools. Spend a little, get a lot!

More about Successful Project Completion ("FFE")

If you have read the post about “Successful Project Completion” then this post helps with some critical details: the concepts of FFE and fixed FFE (i.e. “Furniture, Fixtures, and Equipment”)

FFE (fixed or otherwise) is needed to complete your project and isn’t always expressly included in traditional design and construction services. Examples are:

- Security systems (designers and builders don’t want the liability)

- Data and communication systems (often part of the business work flow)

- Furniture and accessories (includes plants and specialties)

- Modular furniture and work stations (often called “cubicles”)

- Decorations (includes wall art)

- Special equipment (cooling systems for computer equipment etc)

Successful Project Completion

At Wilkinson Building Advisors (“WBA”), projects have 3 stages:

- Planning and setup

- Execution and administration

- Project completion

This post is about Project Completion, the stage when the Owner has spent a lot of money and needs to move in and commence operations in order to derive value from the investment.

Wood and heat pumps; old made new again

100 years ago, old-growth trees were used to make columns, girders, and planks for commercial buildings. Butler Square in Minneapolis is a good example of this applied construction technology. It was a sound construction strategy; 100 years of service is impressive. However, limitations arose from the availability of old-growth trees to be used for this purpose.

50 years ago mechanical designers in the Minneapolis area took the innovative step of applying emerging heat pump technology to indoor climate applications. It was revolutionary. Systems were simplified and installed costs plummeted. It was a serviceable technology for many commercial applications.

Fast forward to today, and the old is being made new again. The fabricated, structural timber industry now makes components to build frames and floors without relying on old-growth trees. To the contrary, 12 to 14-year-old trees are farmed and harvested to make glue-laminated products for the construction of timber frames and CLT floor systems (cross laminated timber).

Application of heat pumps is being used for high-efficiency indoor climate systems. The hydronic water piping systems move the energy around the building to where it's needed. The side of the building in sunlight sheds its excess heat (aka cooling) to the shaded side of the building requiring heating. This distribution by way of the heat pumps leads to reduced energy consumption for indoor climate and comfort.

It turns out that the many energy-saving advantages of wood when combined with high-efficiency indoor climate squarely addresses the issues of energy conservation needed in this era of global warming brought by man's activity.

Care taken in the building industry can make a big difference; join the movement!

(see the blog post at this site: “Timber and Advanced Energy Project Planned in the Upper-Midwest.”)

CLT will change construction in the midwest

Cross laminated timber (CLT) is on a tipping point to bring big change to the midwest construction industry that builds in wood. On the face of it, CLT is just another wood floor product, but it is really more than that in many ways.

First the definition: CLT is a large flat panel made from smaller boards, arranged perpendicular to one another, and glued and pressed together. They come in various thicknesses from roughly 3” (3 ply) to 12” (7-9 ply), and in sizes up to 12’x 60’.

From structural engineering perspective, CLT offers a variety of layout patterns for strength and serviceability. From a construction engineering point of view, CLT can be revolutionary with respect to speed up construction. A small crew using light tools and assisted by mobile hoisting machinery can lift and place panels very quickly.

Developers also like CLT because it has the potential of saving building height while preserving volume within the building. After all volume is what brings the rent not building height. The tenants who pay the rent also tend to love the look and feel of the wood ceilings (the exposed underside of CLT floors).

CLT got it started in Europe and then migrated to the Pacific Northwest and West Canada. It's in these locations that plants have sprung up in many projects using CLT have been built. Now the time has come for the Midwest to join the CLT club as the production and distribution systems expand.

Wilkinson Building Advisors is working with various organizations including Katerra based in Seattle to bring the first demonstration projects to the Midwest. Katerra's local representative in the midwest is Pete Kobelt at . Pete has deep experience with CLT products.

Timber and advanced energy project planned in upper-midwest

Wilkinson Building Advisors (formerly Wpg Ltd) is in ongoing conversations and exchange of documents with the several government and private investors in connection with creating several demonstration projects in the upper Midwest.

- The concept is that these projects would engage several intersecting technologies to create low carbon footprint buildings. These technologies are:

- Glue laminated mass timber frames (Glulam) and cross-laminated (CLT) timber floor systems and shaft walls (to resolve lateral loads)

- Structural integrated panels (SIPs) for exterior wall and roof panels (structural integrated panels)

- Interior climate systems (energy exchange, distribution, and ventilation) including technologies to measure/control/report energy consumption in hydronic systems

- Computer-based design and manufacturing control systems

- The combination of the these systems is synergist with respect to reducing the carbon footprint of these buildings:

- Sequestering CO2 in the timber products

- Avoidance of energy expended in concrete production and steel assembly fabrications when appropriate

- Application of enclosure systems designed for extreme climates

- Design of indoor climate systems based on passive, sustainable solutions and using systems avoiding combustion based energy exchange

- "Tinker-Toy" precast concrete assemblies for podiums and selected lateral load resisting systems

- "Building in a box" construction management techniques; sequential shipment to tight sites, erection by small efficient crews

- A high degree of off-site completion for the "kit of parts" as well as modular assemblies

- The scale and geographic distribution of these projects is intended to showcase the possible and bring the market to a tipping point. These initiatives target 2 prototypical markets

- Urban, infill, mixed use; small scale, 40-75,000sf, 3-5 stories; suitable for building in congested and complex urban environments

- Private higher education, classroom addition or environmental science building; embodying the sense of mission of the institution

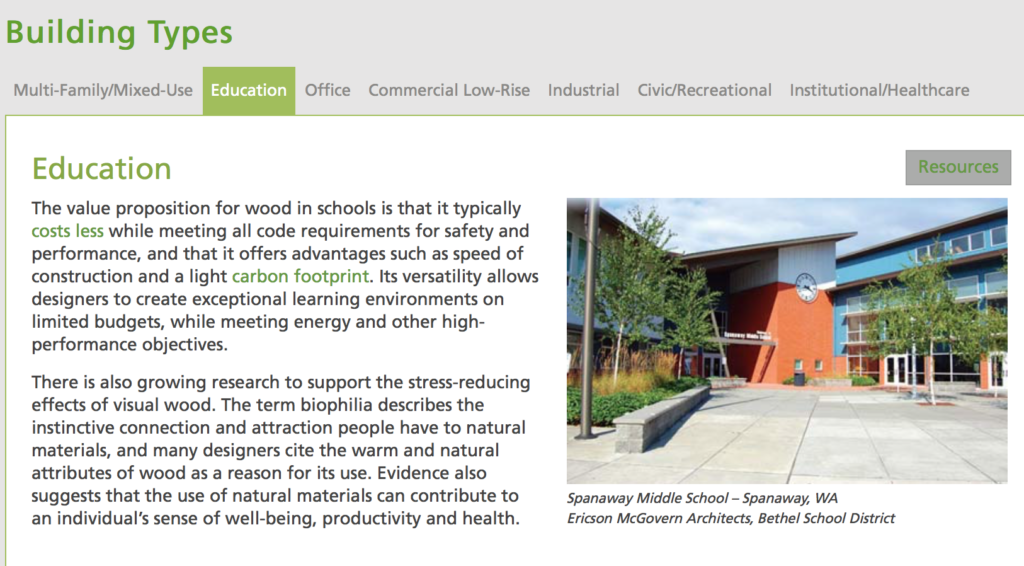

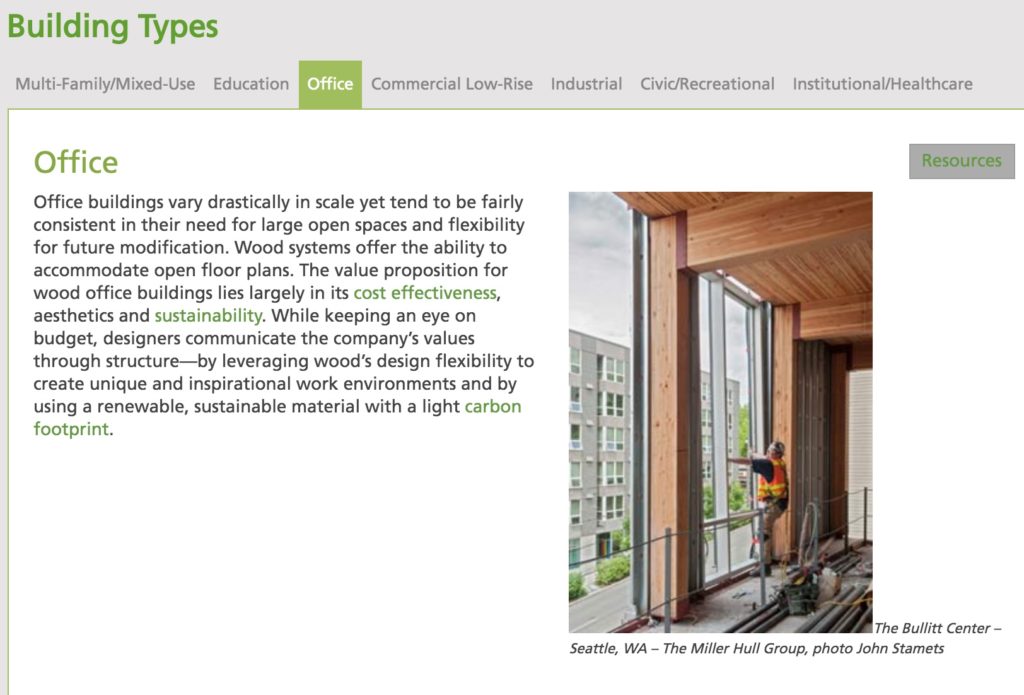

- Here are snippets of the ideas from Woodworks, a leading building advisory group:

This author believes that demonstration projects, well executed, can attract the attention of both policy and market-makers. The walk-through, “touch and feel” experience of these proposed and delightful places can be compelling. As the marketing folks would say: it makes the intangible… tangible.

This is a chance to engage a far-flung industry to plan for the benefit of the planet and the quality of life in the upper-midwest. Join the movement!

For Investors; manage your risks, know your costs upfront

A contract is an agreement about how risk is allocated in the deal; risk is priced into the deal. Each party to the contract negotiates for, and eventually agrees to the price of performance. The specter of risk sits on the shoulders of the contracting parties. When risk is substantially speculative, as compared to known, then contract negotiations and subsequence performance are distorted.

Many processes in the AEC+dev industry are “poster children” to the proposition of contract and performance distortion resulting from mis-allocated risk. Cost ignorance is high among the usual suspects.What is the probability of project successful when this outcome is premised upon blind hope in lieu of skilled calculation?

Don't mix up the details in design problem solving

Gunter Dittmar was my icon in graduate school. He was a despondent German expatriate bombed into depression while growing up in Berlin during the Allied blitz. Amid his slow and thoughtful speech was a bit of genius. He understood that the "problem solving process" and the “problem seeking process” involved keeping the "levels of abstraction" aligned and not mixed up.

For example, you can't solve the big picture if you're focused too early on how many doorknobs and how much they cost each. Ultimately you care about the doorknobs, but only in the right sequence and at the right time.

“The is nothing more worrisome that the wrong question answered well” (quote from South American Architect on TED talks)

The reasons for the mix-ups are many are 1) participants competing for influence in the process and sowing mixed levels just to be in the conversation, 2) sometimes the logical structure of the issue is simply misunderstood and the conversationalists get down the rabbit hole, 3) the participating silos have standards of practice that run in opposition to one another, 4) the participants don't like one another, and 5) disorderly allocation of risk (hours of effort in dollars) etc .

In any event put first things first as you move from concepts to details.